(1) First of all, the hole needs to be reserved, simply put, leave a hole of the right size.

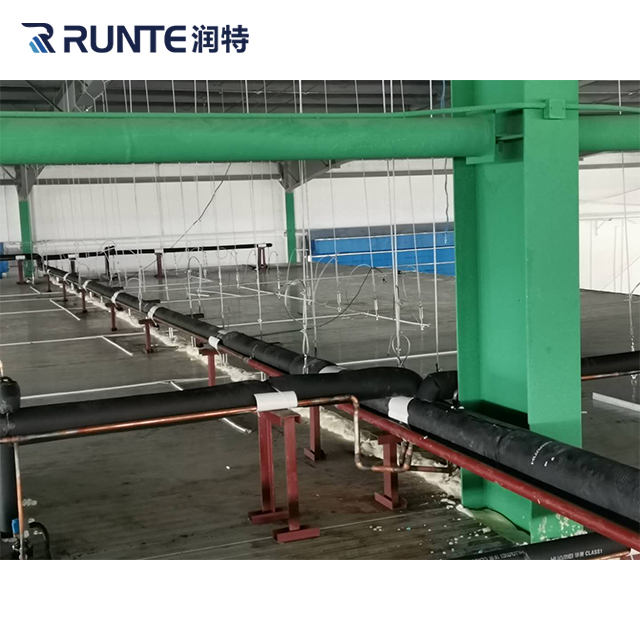

(2) refrigerant pipe insulation pipe need to carry out some protection, generally before we need to use the wrapping tape in advance for wrapping, in the place over the floor using steel casing for pipe protection.

(3) the choice of drainage pipe materials and installation. Drainage pipe installation before you need to determine the material, generally are used pvc or PPR engineering plastic pipe.

Installation steps are roughly divided into four steps.

Connecting the water pipe → laying heating wire → checking water leakage →nsulation

Pipes need to be cleaned up before installation, the dirt inside out, the installation of the standstill period of the pipeline to seal and save. The shorter the length of the pipe in the cold storage, the better, to ensure that the sealing of the pipe, to ensure that there is no leakage before, in particular, the library machine condensate tray drain, should be higher than the drain pipe interface after the PVC piping using a special PVC adhesive connection. After the completion of the pipeline installation needs to be flushed system, the system can be connected after cleaning.

(4) control lines need to be controlled accordingly, the control line all use shielded wire laying along the refrigerant pipe bundle, the indoor controller partially through the pipe concealed, prohibit the power line and control line bundled together again to prevent interference.

Post time: Sep-05-2024