In the refrigeration industry, the relatively low technical requirements of cold storage panels have attracted a large number of personnel and capital investment. The cold storage board is very important for the cold storage, because the cold storage is different from the ordinary warehouse, the temperature inside the cold storage is generally lower, and for the air temperature, humidity, and environmental requirements are relatively high.

Therefore, when we choose the cold storage board, we must pay attention to the temperature control of the cold storage board, if the cold storage board selection is not good, resulting in the cold storage inside the temperature is difficult to control, it is easy to lead to stored in the cold storage inside the product deterioration, or let the cold storage refrigeration compressor work frequently, wasting more resources and increasing costs. Choosing the right panel is the best way to maintain the cold storage.

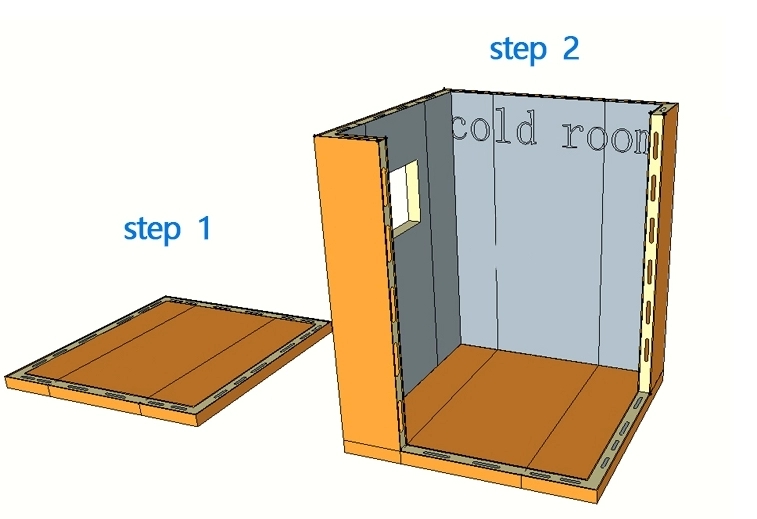

Today, we will mainly focus on three aspects of cold storage panel installation: wall panel installation, roof panel installation and corner panel installation.

Before the installation of cold storage we need to do the corresponding preparatory work, as the saying goes, the work is good at its job must first benefit its tools, materials we must be strict in order to build the best quality cold storage. Cold storage equipment includes roughly: cold storage panels, doors, refrigeration units, refrigeration evaporators, control boxes, expansion valves, copper pipes, control lines, library lights, sealants, etc. These materials are almost every cold storage installation equipment will be used to, but also common materials.

When transporting, it is necessary to take lightly, and to do a good job of anti-scratch measures with the ground. In the installation of the plate needs to be strictly installed according to the design drawings, good before the installation of the plate to do a good number, so that it can be more organized. Cold storage should be installed with the surrounding walls, roofs, etc. to leave a certain distance, to ensure the smoothness of the ground, such as large cold storage need to do a good job of leveling work in advance. If there are slits between the panels, sealant should be used to strictly ensure the thermal insulation performance of the panels and reduce the occurrence of the wind run phenomenon. After the installation of the panels in each direction, you need to use the locking hooks to fix each other to maintain the integrity of the cold storage as a whole.

一. Wall panel installation

1、The installation of wall panel should be started from the corner. In accordance with the plate-laying diagram, two boards need to be installed at the corners to the installation site, according to the height of the board beam and the type of angle iron fixed mushroom head nylon bolts, drill a hole in the middle of the board width at the corresponding elevation position, drilling should be perpendicular to the board surface, the hole on the mushroom head nylon bolts (nylon bolt body and mushroom head should be sealed with sealing paste), set on the angle iron tightening, tighten the degree of the nylon bolts to make the surface of the board A slight depression is appropriate. When standing wall board, should be in contact with the floor groove of the board padded with foam and other soft materials to prevent damage to the board, two corner wall board from the board floor groove in time after the neutral, should be adjusted according to the placement position of the wall board plane position and the verticality of the board, and check the top elevation of the wall board is correct (straight from the beginning to the end need to check). After the correct position of the wall plate, the angle iron pieces will be welded on the plate beam, fixed inside and outside the package corner (package corner plate on both sides of the inside with the library board contact to play a sealing paste). In the welding angle iron pieces, should be covered with a shield at the corner iron pieces of the warehouse plate, to prevent arc welding when the high temperature of welding burns the warehouse plate and welding slag splash to the warehouse plate.

2、After the installation of two wall panels at the corner, start to install the next wall panel along the corner. The next wall plate should be installed before the ground will be convex groove or groove of the board to play two white sealing paste (sealing paste should be played in the corner of the convex groove or groove of the board), playing in the convex groove or groove inland sealing paste paste should be a certain height, should also be dense and continuous uniform, the installation method is the same as the first wall plate.

3, between the two library board first with a hammer to hit the pad in the polyurethane library board on the place wood, so that the board and the board close together. Two sets of connectors are wedged between the wall plate and the wall plate, and the two sets of connectors are fixed on the outside and the inside of the wall plate and the wall plate gap, and the connectors on the inside of the wall plate should be as far down as possible so that the concrete can cover the connectors after pouring. The gap between the board and the board should be kept at about 3mm wide after wedging with the connectors, if it does not meet the nuclear requirements, the board will be removed, the board edge will be repaired, and then the board gap will be reinstalled to meet the requirements. When fixing the connector, we should pay attention to the two parts of a set of connectors are fixed in the edge of the convex and concave two plates, fixed with φ5X13 rivets, the distance of the connector to be able to pull the two plates tightly as appropriate. When wedge tightening wedge iron, hammer and wedge iron to maintain vertical, avoid touching the board, the upper and lower parts of the wedge iron should be wedged tightly at the same time, fixed with rivets wedge iron.

二、 the installation of the top plate

1、Before installing the top plate, the ceiling should be installed with T-iron according to the drawing. When installing the T-iron, the T-iron should be properly arched according to the span of the rigid frame to ensure that the T-iron does not produce downward deflection after the installation of the top plate. The installation of the top plate should start from the corner of the warehouse body, and according to the plate-laying diagram, the warehouse plate should be raised to the specified height and position, and the longitudinal plate end of the warehouse plate should be placed on the wall plate and T-iron respectively. Adjust the parallelism and verticality of the coaxial line of the top board, review the elevation of the bottom surface of the top board, then fix the top board with T-iron with pull rivets, connect the top board with the corner board between the wall board, and then start the installation of the next board.

2, the second top plate installation method is basically the same as the first plate, board board connection method is basically the same as the installation of the wall plate. The connection should be fixed outside the warehouse, each warehouse board slit should be fixed three warehouse board connections, one at each end of the warehouse board and one in the board (the length of the top board is less than 4 meters, two warehouse board connections are also available).

3、After the installation of all the top plates, start the installation of ceiling C-beam. According to the actual row of the top plate, on the ground will be fixed mushroom head nylon bolts angle iron pieces according to the corresponding spacing welded in the ceiling C-shaped steel. Then put the ceiling C-beam in the corresponding position of the top plate according to the drawing, and the ceiling C-beam should ensure the parallelism and verticality of the coaxial line. After adjusting the position of the ceiling C-beam, open the hole of the top plate in the position of the bolt hole of the angle iron piece, and connect the angle iron piece with the warehouse plate firmly with the mushroom head nylon bolt. After that, weld the ceiling C-beam to the purlin with the round steel pendant, and adjust the nut under the round steel pendant to adjust the ceiling C-beam and the top plate to the specified height according to the elevation of the bottom of the top plate.

三、the installation of the corner board

All cold storage corner boards are sealed with a sealing paste on the inside of both sides and the contact of the board. The corner cladding between the wall panels should be fixed in sections to facilitate the pouring of polyurethane foam on site. Fixed top board corner board should be cut every 500mm with iron shears an opening (the size of the opening to be able to enter the foam material shall prevail), and then it will be fixed on the top board and the wall board. The corner board should be fixed with pull rivets, and the spacing between pull rivets should be kept at 100mm, and the pull rivets fixed on the corner should be in a straight line with equal spacing. Pay attention to the drilling of rivets and the use of rivets to fix the rivets, the tool used should be vertical with the corner board.

Post time: May-23-2023